Consider the brass alloy for which the stress-strain behavior is a crucial factor in determining its mechanical properties and performance in various applications. Understanding the stress-strain behavior of brass alloys is essential for engineers and designers to optimize the design and performance of components and structures.

Brass alloys are widely used in various industries due to their excellent mechanical properties, such as high strength, ductility, and corrosion resistance. The stress-strain behavior of brass alloys is influenced by several factors, including alloy composition, heat treatment, and cold working.

By understanding the stress-strain behavior, engineers can select the appropriate brass alloy for specific applications and optimize its performance.

Introduction: Consider The Brass Alloy For Which The Stress-strain Behavior

The stress-strain behavior of brass alloys is crucial for understanding their mechanical properties and performance in various applications. This behavior influences factors such as tensile strength, yield strength, and elongation, which are essential for designing and engineering components using brass alloys.

By considering the stress-strain characteristics, engineers can optimize the selection and utilization of brass alloys to meet specific requirements and ensure their reliable operation in demanding applications.

Mechanical Properties of Brass Alloys, Consider the brass alloy for which the stress-strain behavior

The mechanical properties of brass alloys are determined by their composition, heat treatment, and cold working. The tensile strength, yield strength, and elongation are key indicators of the material’s strength and ductility.

- Tensile strengthrepresents the maximum stress a brass alloy can withstand before fracturing.

- Yield strengthindicates the stress at which the alloy begins to deform plastically.

- Elongationmeasures the material’s ability to stretch before breaking.

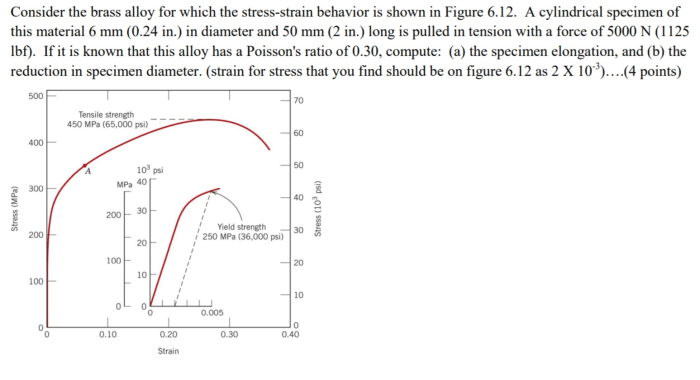

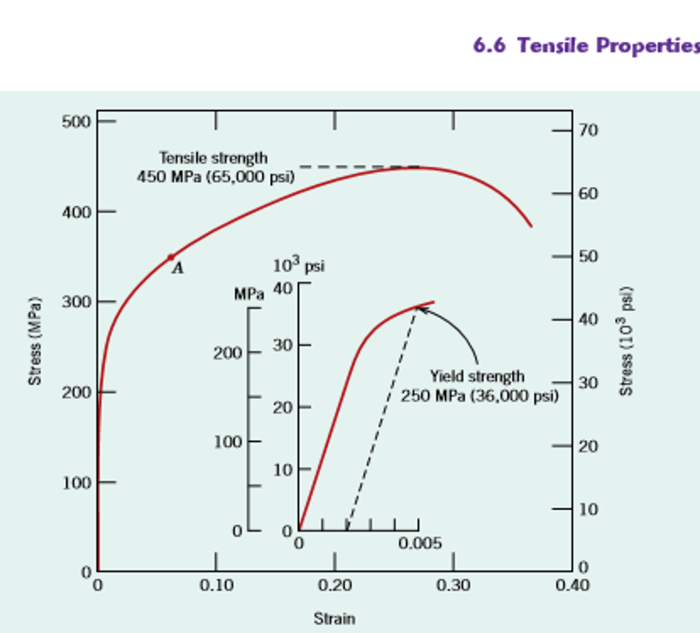

Stress-Strain Curves for Brass Alloys

The stress-strain curve provides a graphical representation of the stress-strain behavior of a brass alloy. It exhibits a linear elastic region, a yield point, and an ultimate tensile strength.

The yield pointmarks the transition from elastic to plastic deformation, while the ultimate tensile strengthrepresents the maximum stress the alloy can withstand.

Applications of Brass Alloys

Brass alloys are widely used in various applications due to their combination of strength, ductility, and corrosion resistance.

- Musical instruments: Brass alloys are commonly used in wind instruments due to their ability to produce a warm and resonant sound.

- Hardware: Brass alloys are employed in hinges, doorknobs, and other hardware components due to their durability and resistance to wear and tear.

- Electrical components: Brass alloys are used in electrical connectors and terminals due to their good electrical conductivity and corrosion resistance.

Design Considerations for Brass Alloys

When designing components using brass alloys, it is essential to consider their stress-strain behavior to ensure optimal performance and reliability.

The selection of the appropriate brass alloy depends on factors such as the required strength, ductility, and corrosion resistance. The stress-strain curve provides valuable insights into the material’s behavior under different loading conditions.

Testing and Characterization

The stress-strain behavior of brass alloys is typically characterized using tensile testing. This technique involves subjecting a specimen to a controlled tensile load and measuring the resulting strain.

Other mechanical testing techniques, such as hardness testing and impact testing, can also provide complementary information about the material’s properties.

FAQ Compilation

What is the significance of understanding the stress-strain behavior of brass alloys?

Understanding the stress-strain behavior of brass alloys is important because it provides insights into the mechanical properties of the material. It helps engineers predict how the material will behave under different loading conditions, which is crucial for designing and optimizing components and structures.

How does alloy composition affect the stress-strain behavior of brass alloys?

Alloy composition significantly influences the stress-strain behavior of brass alloys. Different alloying elements can alter the strength, ductility, and other mechanical properties of the material. For example, increasing the zinc content in brass alloys generally increases the strength and hardness but reduces the ductility.

What are the applications of brass alloys where the stress-strain behavior is crucial?

Brass alloys are used in various applications where the stress-strain behavior is crucial, such as musical instruments, jewelry, marine hardware, and automotive components. In musical instruments, the stress-strain behavior affects the tone and resonance of the instrument. In jewelry, it influences the durability and wear resistance of the pieces.

In marine hardware, it ensures the reliability and safety of components exposed to harsh environments.